-

Hours

Tuesday, Thursday, Friday & Saturday

11:00 am - 1:00 pm -

Shop Online

Shop online and pick up in person seven days a week. We pack and ship daily.

-

Make an Appointment

Contact us if you'd like to make an appointment to visit the shop or get your knives sharpened,

Skarpari Is the Icelandic Word for Sharper

Skarpari is a family-owned and operated business that has been handcrafting knives in the San Juan Islands since 2015. We take pride in our work and are passionate about making the highest-quality knives possible. In addition to knives, we also offer sharpening services, seasonal food items, and organic roasted coffee. Our goal is to provide our customers with unique products they cannot find anywhere else. Whether you are looking for a unique gift or something to remind you of your time in the San Juans, Skarpari has you covered.

Available Skarpari Knives

-

3" Hand Paring Knife - No. 2233

Regular price $350.00 USDRegular priceUnit price / per -

3" Hand Paring Knife - No. 2234

Regular price $350.00 USDRegular priceUnit price / per -

2.5" Hand Paring Knife - No. 2231

Regular price $350.00 USDRegular priceUnit price / per -

3.75" Bar / Paring Knife - No. 2232

Regular price $300.00 USDRegular priceUnit price / per -

Oyster Skinner - No. 2235

Regular price $250.00 USDRegular priceUnit price / per -

2" Mini Cleaver - No. 2229

Regular price $200.00 USDRegular priceUnit price / per -

5" Santoku - No. 2230

Regular price $650.00 USDRegular priceUnit price / per -

7" Fillet Knife - No. 2221

Regular price $300.00 USDRegular priceUnit price / per -

Bread Knife - No. 2220

Regular price $350.00 USDRegular priceUnit price / per -

7" Fillet Knife - No. 2216

Regular price $300.00 USDRegular priceUnit price / per

Handmade Jewelry

-

Hidden Good Luck Coin Necklace

Regular price $40.00 USDRegular priceUnit price / per -

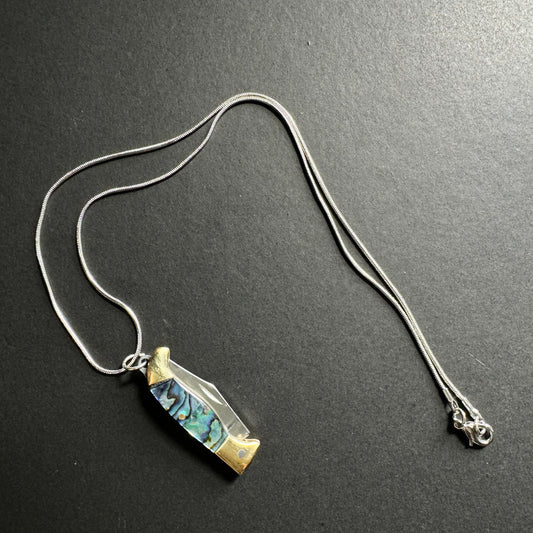

Mother of Pearl Gold and Silver Knife Necklace

Regular price $40.00 USDRegular priceUnit price / per -

Silver Fish Folding Knife Necklace

Regular price $40.00 USDRegular priceUnit price / per -

Green Glass Skull Necklace

Regular price $40.00 USDRegular priceUnit price / per -

Jackel Tooth Earrings

Regular price $35.00 USDRegular priceUnit price / per -

Alder Pearl Earrings

Regular price $35.00 USDRegular priceUnit price / per -

Handmade Pinecone Earrings

Regular price $35.00 USDRegular priceUnit price / per -

Evil Eye Dangling Earrings

Regular price $35.00 USDRegular priceUnit price / per -

Gold Evil Eye Necklace

Regular price $40.00 USDRegular priceUnit price / per -

Mushroom Enamel Pin

Regular price $10.00 USDRegular priceUnit price / per

Home Goods

-

Handblown Glass Flowers

Regular price From $35.00 USDRegular priceUnit price / per -

Wood and Glass Candle Lantern

Regular price $30.00 USDRegular priceUnit price / per -

Patterned Wooden Kitchen Utensils

Regular price $30.00 USDRegular priceUnit price / per -

Handmade Ceramic Cone Espresso Cup with Base

Regular price $30.00 USDRegular priceUnit price / per -

Wood and Ceramic Espresso Cup

Regular price $30.00 USDRegular priceUnit price / per -

Metal and Glass Mini Lantern

Regular price $30.00 USDRegular priceUnit price / per -

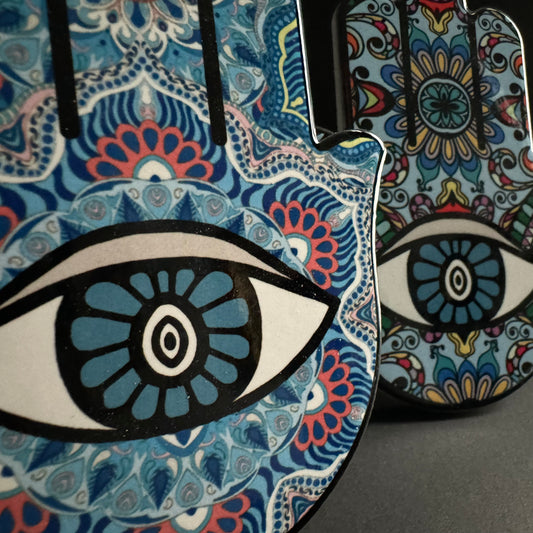

Ceramic Evil Eye Hand Decoration

Regular price $30.00 USDRegular priceUnit price / per -

Hand Carved Wood Coffee Mug

Regular price $30.00 USDRegular priceUnit price / per -

Glass and Wood Ceramic Pour Over Coffee Pot

Regular price $60.00 USDRegular priceUnit price / per -

Glass Mushroom Shaped Vase

Regular price $40.00 USDRegular priceUnit price / per

Accessories

-

Handmade Ceramic Leaf Whistle Necklace

Regular price $40.00 USDRegular priceUnit price / per -

Handmade Crochet Lavender

Regular price $10.00 USDRegular priceUnit price / per -

Sun Catcher Window Decals

Regular price $11.11 USDRegular priceUnit price / per -

Everyday Carry Novelty Good Luck Coin

Regular price $20.00 USDRegular priceUnit price / per -

Brass Figurines

Regular price $20.00 USDRegular priceUnit price / per -

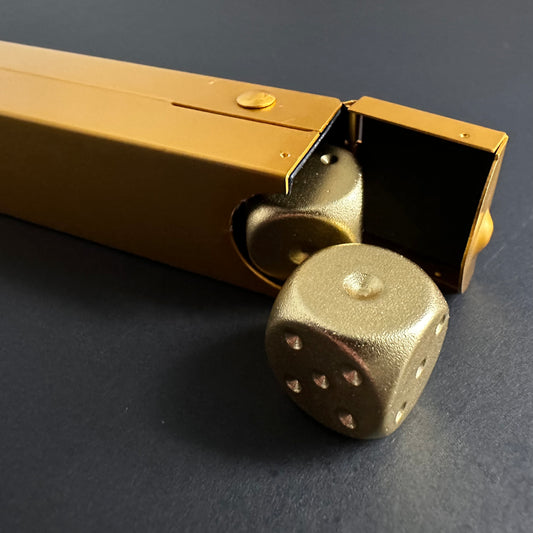

Gold Metal Dice Set with Carrying Case

Regular price $30.00 USDRegular priceUnit price / per -

Natural Healing Clear Quartz Crystal

Regular price $4.44 USDRegular priceUnit price / per -

Moon Moth Lopez Island, WA Stickers

Regular price $5.00 USDRegular priceUnit price / per -

Divination Pendulum Altar Cloth

Regular price $5.55 USDRegular priceUnit price / per -

Gemstone Chakra Hexagonal Pendulum

Regular price $8.88 USDRegular priceUnit price / per

Shop All Products

-

Handblown Glass Flowers

Regular price From $35.00 USDRegular priceUnit price / per -

Wood and Glass Candle Lantern

Regular price $30.00 USDRegular priceUnit price / per -

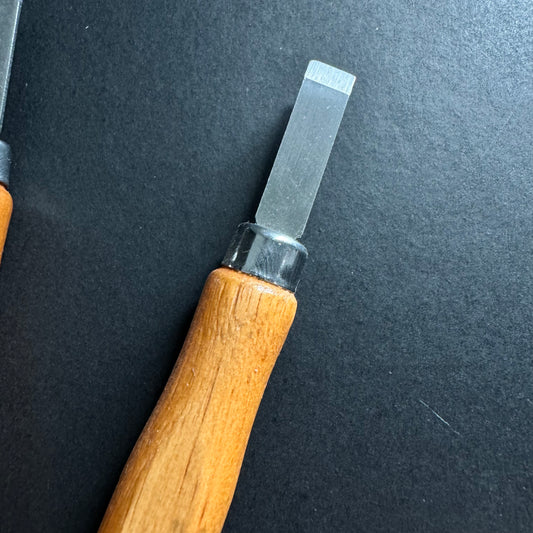

Wood Carving Small Tool Set

Regular price $65.00 USDRegular priceUnit price / per -

Patterned Wooden Kitchen Utensils

Regular price $30.00 USDRegular priceUnit price / per -

Handmade Ceramic Cone Espresso Cup with Base

Regular price $30.00 USDRegular priceUnit price / per -

Wood and Ceramic Espresso Cup

Regular price $30.00 USDRegular priceUnit price / per -

Metal and Glass Mini Lantern

Regular price $30.00 USDRegular priceUnit price / per -

Hidden Good Luck Coin Necklace

Regular price $40.00 USDRegular priceUnit price / per -

Mother of Pearl Gold and Silver Knife Necklace

Regular price $40.00 USDRegular priceUnit price / per -

Silver Fish Folding Knife Necklace

Regular price $40.00 USDRegular priceUnit price / per

Skarpari

Skarpari Lopez Island Organic Suncatcher Coffee

Share

Journal

View all-

Skarpari in the Press

Chris + Krista StovallSkarpari on Seattle Refined Read the full article here. Skarpari on Travel Awaits Read the full article here. Skarpari on Everout.com Read the full article here.

Skarpari in the Press

Chris + Krista StovallSkarpari on Seattle Refined Read the full article here. Skarpari on Travel Awaits Read the full article here. Skarpari on Everout.com Read the full article here.

-

Introducing the Skarpari Fillet Knife: The Perf...

Chris + Krista StovallWhat makes the Skarpari Fillet Knife stand out? When it comes to filleting fish, precision is key. That's where the Skarpari Fillet Knife comes in. This exceptional tool is designed...

Introducing the Skarpari Fillet Knife: The Perf...

Chris + Krista StovallWhat makes the Skarpari Fillet Knife stand out? When it comes to filleting fish, precision is key. That's where the Skarpari Fillet Knife comes in. This exceptional tool is designed...

-

The Fourth of July: A Spectacular Celebration o...

Chris + Krista StovallLopez Island, nestled in the heart of Washington State, holds a significant and cherished tradition for celebrating the Fourth of July. This small, tight-knit community has established itself as a...

The Fourth of July: A Spectacular Celebration o...

Chris + Krista StovallLopez Island, nestled in the heart of Washington State, holds a significant and cherished tradition for celebrating the Fourth of July. This small, tight-knit community has established itself as a...

-

Outstanding In The Field, Lopez Island, Washing...

Chris + Krista StovallAs the summer sun warms the breathtaking landscapes of Lopez Island, Washington, the "Friendly Isle" prepares to host a one-of-a-kind event that promises to be a feast for the senses....

Outstanding In The Field, Lopez Island, Washing...

Chris + Krista StovallAs the summer sun warms the breathtaking landscapes of Lopez Island, Washington, the "Friendly Isle" prepares to host a one-of-a-kind event that promises to be a feast for the senses....